View More

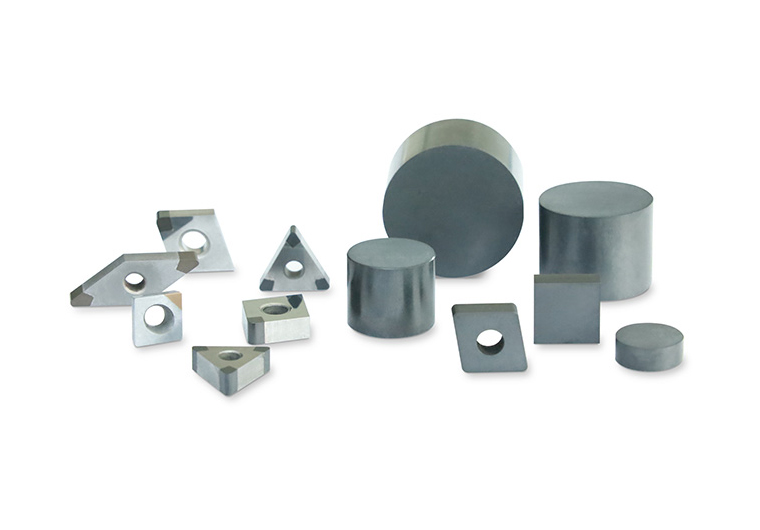

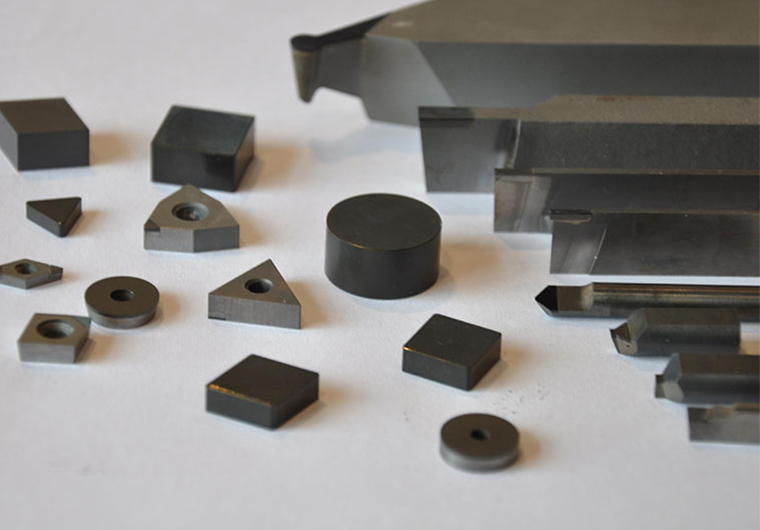

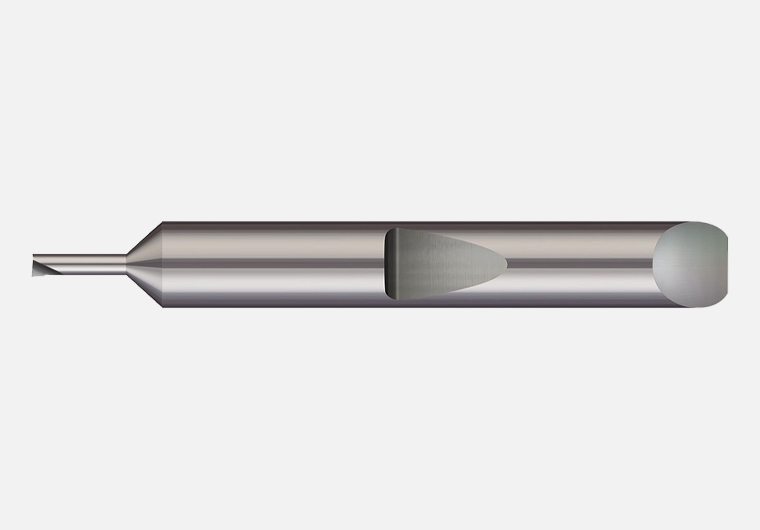

PCD inserts

PCD insert is mainly used for machining non-ferrous metal. In engine industry, it achieves great machining result when machining die casting aluminum.

Product Description:

PCD insert is mainly used for machining non-ferrous metal. In engine industry, it achieves great machining result when machining die casting aluminum.

Advantages of PCD inserts:

1.High wear resistance and long tool life, reducing the cost.

2.No sticky chips prolong the tool life,saving the time of changing tools.

3.Suitable for mass production, regrinding service offered.

PCD inserts grades:

|

Workpiece |

Cutting conditions |

||

|

Cutting speed (m/min) |

Feed (mm/r) |

Cutting depth (mm) |

|

|

Si<13% aluminum alloy |

600-2400 |

0.1-0.4 |

0.1-0.3 |

|

Si> 13% aluminum alloy |

300-700 |

0.1-0.4 |

0.1-0.3 |

|

Copper alloy |

400-1200 |

0.05-0.3 |

0.05-2.0 |

|

Carbide hard alloy |

20-40 |

0.1-0.25 |

0.1-1.0 |

|

Ceramic |

70-100 |

0.1-0.4 |

0.2-1.0 |

|

Wood |

1000-4000 |

0.1-0.4 |

0.2-4.0 |

|

Composite |

200-2000 |

0.05-0.3 |

0.1-3.0 |