View More

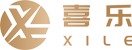

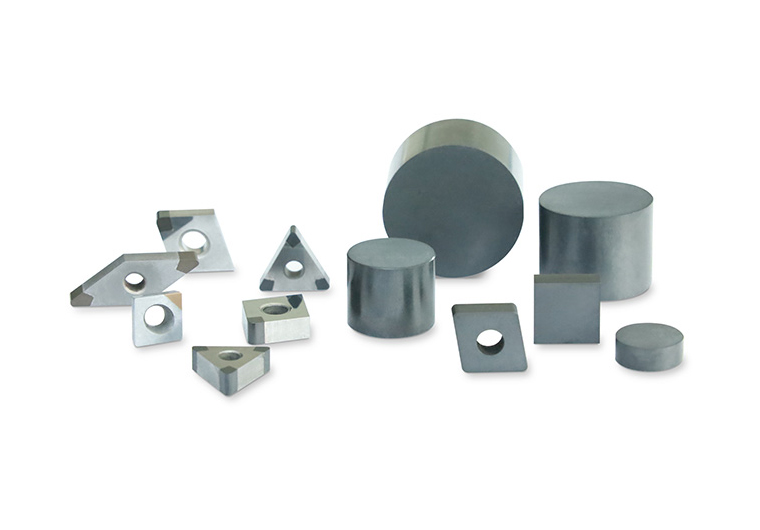

CBN inserts

CBN inserts are widely used in processing pearlitic cast iron, high chromium and nickel alloy cast iron, hardened steel, powder metal, hard alloy and super alloy.

Product Description:

CBN inserts are widely used in processing pearlitic cast iron, high chromium and nickel alloy cast iron, hardened steel, powder metal, hard alloy and super alloy. In the mechanical machining application of the traditional system, not only it has greatly reduced the comprehensive production cost, but also significantly improved the production capacity and efficiency during the whole production operation, and the equipment investment is greatly decreased at the same time.

Advantages of CBN inserts:

High machining efficiency

The machining efficiency of CBN insert is 5-10 times that of the carbide insert, which greatly improves the equipment capacity and reduces the fixed investment of equipment.

Excellent cost performance

The service life of CBN insert can be more than 10 times that of carbide insert and reduce the cost of comprehensive cutting tool by 30%-50%. The interval time between the replacements of CBN insert is long and the insert replacement frequency is less, which can significantly reduce the cost on inserts.

Excellent surface quality

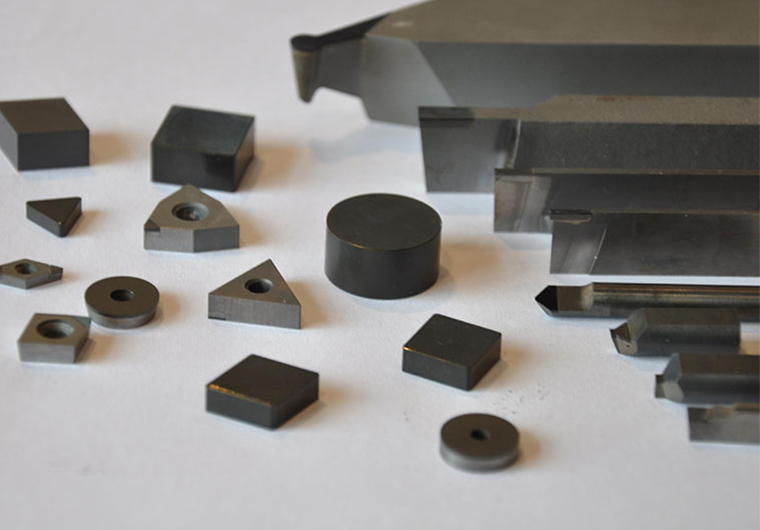

Surface finish and dimensional precision of machining workpiece of CBN insert can reach the grinding level, and make turning instead of grinding to reduce equipment investment.

Strong universality

CBN insert can be used for both dry cutting and wet cutting and one grade normally is suitable for machining a variety of materials.

PCBN inserts grades:

|

Workpiece |

Cutting conditions |

||

|

Cutting speed (m/min) |

Feed (mm/r) |

Cutting depth (mm) |

|

|

Hardened steel (>45HRC) |

100-250 |

0.05-0.15 |

0.1-0.3 |

|

Mould steel |

90-110 |

0.1-0.2 |

0.1-0.5 |

|

Gray cast iron |

400-1500 |

0.05-0.15 |

0.1-0.3 |

|

Hard cast iron |

40-100 |

0.05-0.15 |

0.1-0.3 |

|

Tungsten carbide |

20-40 |

0.1-0.25 |

0.1-1.0 |

|

Powder metallurgy |

70-250 |

0.025-0.2 |

0.05-0.2 |